"We wanted to use the tests to find out how different materials react to the various consumables within individual processes," explains Markus Geßner, Head of Marketing and Sales at Emil Otto. In the first test, the common materials processed by Leutz, such as titanium, aluminum, ESD-compliant plastics and GRP, were treated with different alcohol-based, water-based and hybrid fluxes and exposed to temperature ranges that are reached in soldering processes. "From the range of alcohol-based fluxes, S-250/FR and S-250/FRO, all GSP products and all fluxes from the EO-B series were tested. In the case of water-based fluxes, on the other hand, we tested all fluxes and all hybrid fluxes," explains Geßner in retrospect.

"During these intensive tests, we were able to simulate the classic use of a workpiece carrier or painting frame," adds Nicole Leutz, Managing Director of Leutz Lötsysteme. None of the Emil Otto fluxes used attacked the different materials or changed the structure or color of the respective surface. The use of Emil Otto fluxes in combination with Leutz products is therefore possible without restriction.

S-250/FR

Wave soldering (spray and foam fluxing)

No Clean-Flux, alcohol-based

Di-carboxylic acids, synthetic resin, halide-free (WEEE/RoHS-compliant)

Type ISO-9454: 1231 // DIN EN 61190-1-1 (according to J-STD-004) (IEC: REL0)

S-250/FRO

Wave soldering (spray fluxing)

No Clean-Flux, alcohol-based

Di-carboxylic acids, synthetic resin, halide-free (WEEE/RoHS-compliant)

Type ISO-9454: 1231 // DIN EN 61190-1-1 (according to J-STD-004) (IEC: REL0)

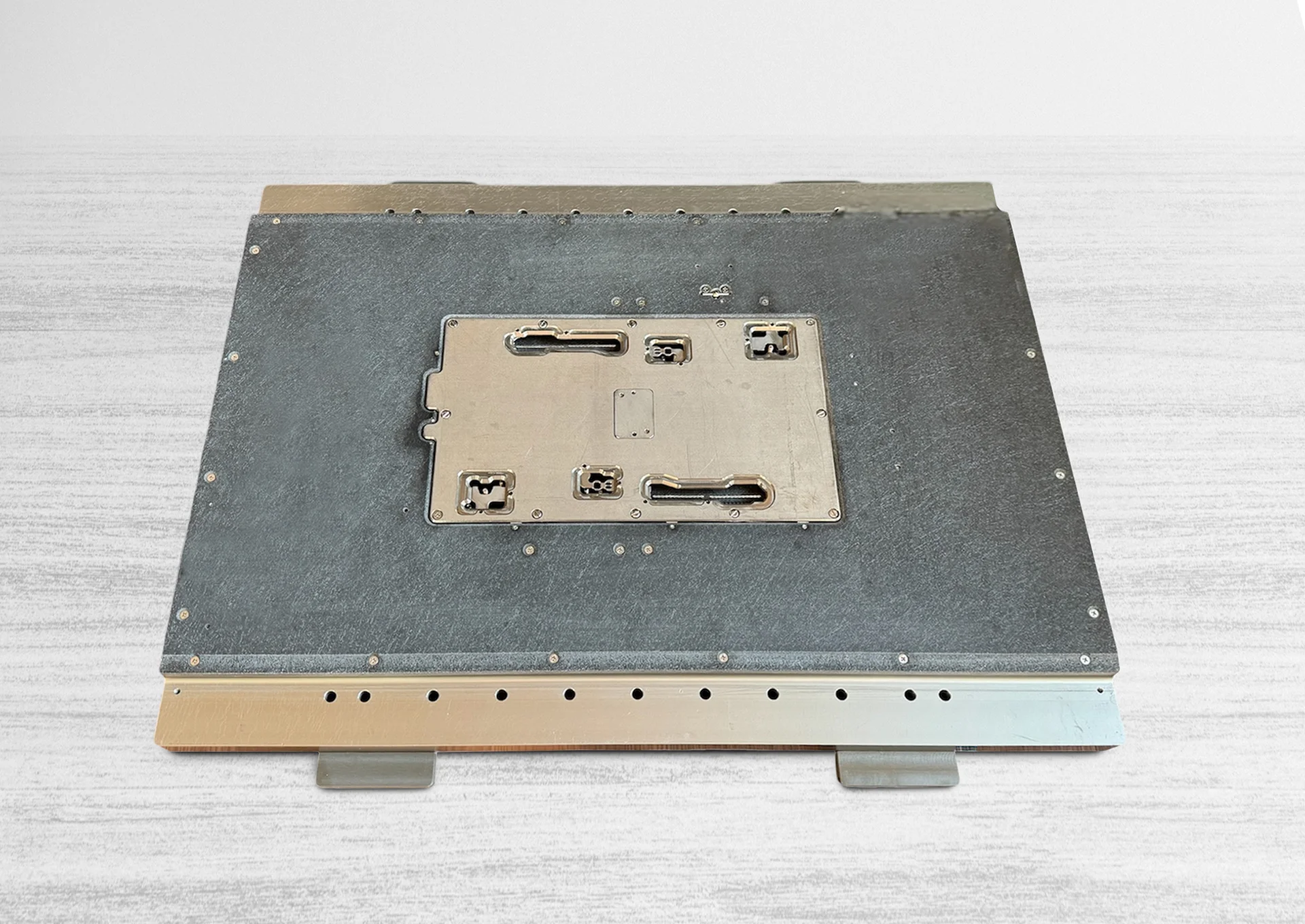

The workpiece carriers from Leutz Lötsysteme are used as precisely fitting holders for components and assemblies for use in automated inline production and are usually made of metal or plastic. The individual carriers are designed and manufactured on the basis of customer-specific specifications and requirements. The aim is to ensure optimum positioning of the components in the workpiece carrier and thus a high level of repeat accuracy in automation. The same applies to the specifically manufactured soldering and painting fixtures, as well as the product-specific painting carriers for painting one or both sides of assemblies. "Our customers expect our products to have a long service life, which must not be reduced by the use of consumables. That's why the test with Emil Otto products was important to us," says Nicole Leutz.

In addition to the various fluxes, Etimol cleaners from the Emil Otto portfolio were also tested. "We processed all of Leutz's soldering frames, workpiece carriers and painting frames with our Etimol products and subjected them to a regular cleaning process, as occurs in every electronics production facility," continues Geßner. Various soldering system cleaners from the Etimol SEM 10, 11 and 12 series, which can be used to clean soldering frames, were tested. These cleaning media are ready-to-use, water-based cleaning agents that can also be used for machine cleaning in reflow, wave, selective and vapor phase soldering systems. "We also used Etimol SEM 13 RAA, our strongest system cleaner," adds Geßner. The water-based solder frame cleaners Etimol PC 50 RAA and Etimol PC 55 CA, which can also be used for cleaning condensate traps, were also put to the test.

While Etimol PC 55 CA is a concentrate that can be diluted with DI water, Etimol PC 50 RAA is a ready-to-use mixture. Both products achieve exactly the same cleaning effect. For the test on painting frames, however, Emil Otto chose the common cleaners Etimol CR 65 RS and Etimol CR 66 RSA, which can also be used to remove silicone, acrylate and urethane paints and can be used for conformal coating.

"None of the cleaners tested attacked the surfaces of the soldering frames, workpiece carriers and painting frames manufactured by Leutz or changed their color or structure," points out Geßner. Nicole Leutz adds: "Our products are very compatible with the fluxes and cleaning agents from Emil Otto. This is a good combination, as it reliably ensures a long service life for our workpiece carriers and painting frames."

On October 23, both companies will be presenting their products together with other partners at the Leutz in-house exhibition. Visitors are cordially invited.

Etimol PC 55 CA

Solder frame and condensate trap cleaning

Water-based ETIMOL concentrate

Etimol PC 50 RAA

Solder frame and condensate trap cleaning

Water-based, ready-to-use ETIMOL

Etimol CR 65 RS

Cleaning of painting frames (conformal coating) to remove silicone paints

Solvent-based, ready-to-use Etimol