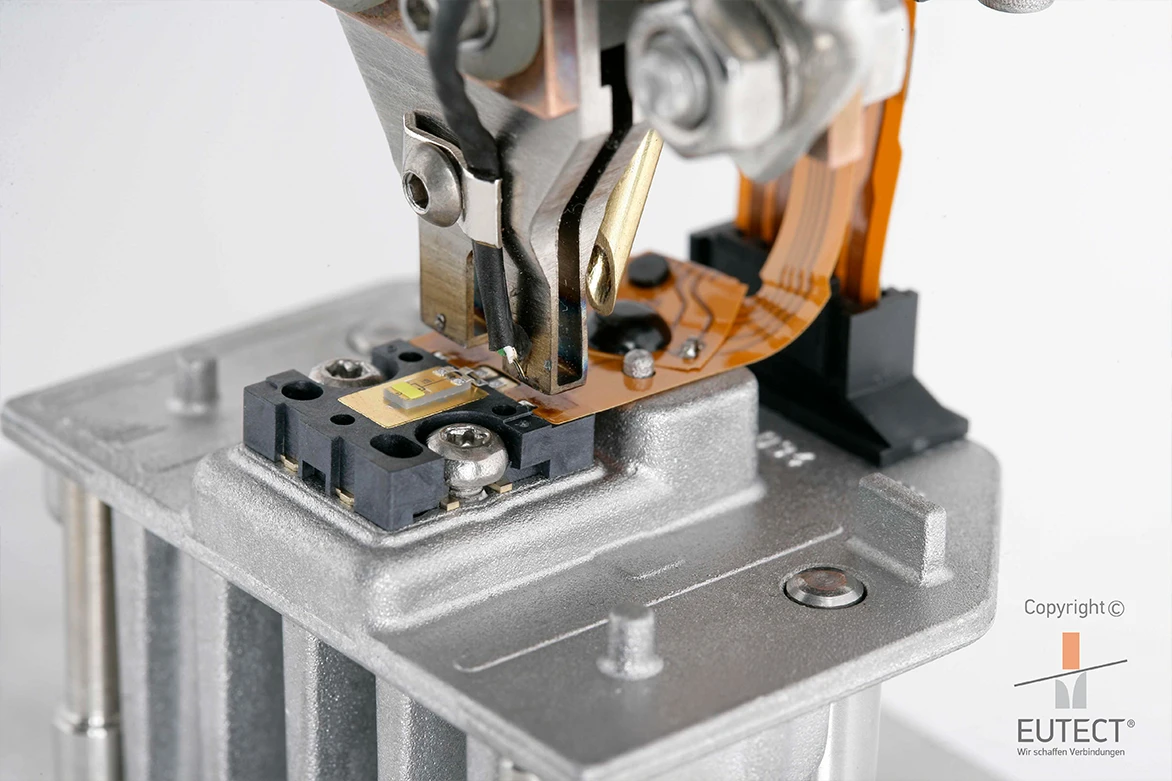

The use of flux during thermode soldering removes oxide layers and impurities to enable optimum wetting of the solder. As the solder flows evenly, a stable connection is created. The flux

HTW-48

Dip tinning, selective and manual soldering processes, strand tinning

No Clean flux with halide-free activators (WEEE /RoHS compliant)

Type ISO-9454: 1131 DIN EN 61190-1-1 (according to J-STD 004) ROL0

HTW-49

Dip tinning, selective and manual soldering processes, strand tinning

No Clean flux with halide-free activators (WEEE /RoHS compliant)

Type ISO-9454: 1131 (1.1.3.A) DIN-EN 61190-1-1 (according to J-STD-004): ROL0

Especially for selective soldering processes and cable assembly

The flux

Suitable as flux gels for repair tasks on assembled printed circuit boards

Both fluxes are also available as gels for reworking, which are particularly suitable for repair work on assembled PCBs. In the past, it was often necessary to use fluxes for manual and repair soldering, which, however, use different activators. By using standardized activators, cross-reactions can be avoided, which can occur when using different activators from different products.

The new flux gels are based on the activator formulation of the fluxes

The flux that has been available on the market for a long time