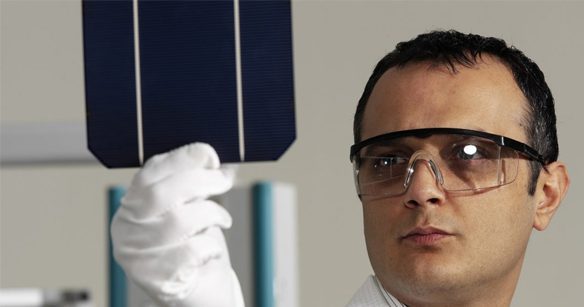

Thanks to its broad development expertise, Emil Otto GmbH has been offering special fluxes for individual and combined applications as well as for individual branches of industry and manufacturing processes for many years. The development of fluxes for the solar industry was therefore only a small step. "We have been working for years on fluxes that leave virtually no residue after the soldering process. We have now developed products that fulfill this criterion perfectly. It is precisely this property of a flux that is particularly important for the solar industry, as impurities on the solar cell have a negative impact on effectiveness," explains Markus Geßner, Head of Marketing and Sales at Emil Otto GmbH.

Emil Otto currently offers three fluxes: EO-S-001, EO-S-002 and EO-S-007. Further fluxes will follow in the course of the second half of the year. All fluxes have been developed for soldering solar modules, tabber and stringer material, as well as for connecting cells. Furthermore, the products are NO-CLEAN fluxes, which are formulated halogen-free. All fluxes leave no sticky residues. Process tests with well-known machine manufacturers from the stringer technology sector prove this. Furthermore, the activators are specially designed for the high temperatures required in the production of solar modules without impairing the efficiency of the activators. This also applies to the actual application in particularly sunny and hot regions. "The flux residues must remain stable even when exposed to high heat from solar radiation. Resins that become soft and liquefy can have a decisive impact on the effectiveness of a solar module. This must be prevented," explains Geßner. The solid content is between 1.5 and 2.5%, depending on the flux.

In addition to 5 and 20 liter canisters, the solar fluxes are also available as a concentrate. "These packaging units are particularly interesting for customers who purchase large quantities or manufacture abroad," explains Geßner. This is because all granulates from Emil Otto can be transported without hazardous substance identification and in greatly reduced volumes. "A flux becomes a hazardous substance if it contains alcohol, for example. Our granulates are free of this because the customer adds the alcohol on site," says Geßner. Furthermore, the granules can be packaged more simply and in smaller volumes, which reduces transportation costs. Thanks to these transport optimizations, the flux concentrates can be transported over long distances in a very economically attractive way, as freight forwarders charge much lower costs for non-hazardous goods. "Mixing the flux on site is very simple. Each granulate comes with the necessary information on which liquid needs to be added to the concentrate and in what dosage," continues Geßner.