Quality products for soft soldering a wide range of metals

In soft soldering, metals are joined together using solder at process temperatures below 450 °C. A solder is melted to create a stable connection between the metal surfaces. This method is characterized by its ease of use and suitability for a wide variety of materials. Thorough cleaning of the metal surfaces is essential to ensure a durable and reliable soldered joint. The surfaces must be free of oxides and other impurities for soft soldering. Oxide formation should also be prevented as far as possible during the soldering process.

High-quality products for optimum soldered joints

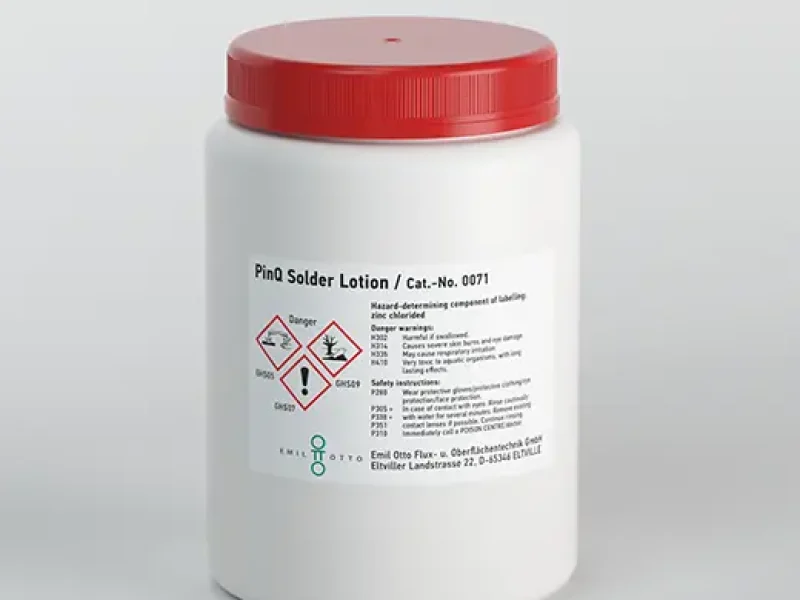

Emil Otto offers a comprehensive range of products that have been specially developed for soft soldering. From flux concentrates and ready-to-use fluxes to soldering lotions, soldering oils, soldering pastes, soldering greases and soldering additives - our portfolio meets the highest standards of quality and functionality. The products not only ensure a reliable connection during soft soldering, but also optimize the soldering process itself.

Our solutions have proven themselves particularly in demanding applications such as copper soft soldering, for example when soldering copper pipes. They ensure a clean and precise connection that remains stable in the long term. Our solder pastes for soft soldering also offer easy handling and enable consistent results, even with complex workpieces.

Flux as the key to success

Fluxes play a central role in soft soldering. Fluxes prevent the formation of oxides during soldering. In addition, fluxes improve the wetting of the metal surfaces and thus ensure a smooth connection. The fluxes and flux gels for soft soldering from Emil Otto have been specially developed to achieve first-class results even with difficult materials such as stainless steel or nickel.

Equally suitable for industry and trade

Our products are designed in such a way that they can be used optimally in industrial series production as well as in trade. With a large selection of different packaging sizes, from small units for occasional use to large packs for professional requirements, we offer flexible quantities for every need.

Perfect results with the right tool

In addition to our fluxes and solder pastes, our soldering additives are also important consumables for reliable soft soldering. Soldering stainless steel with soldering aids such as our soldering grease is the first step towards a clean and durable joint. The soldering greases are used in particular in radiator construction, tool and machine construction, roofing, installation and plant construction as well as measurement and control technology. With the support of Emil Otto's high-quality products, every soldering process, whether with soft solder or special soldering pastes, can be carried out efficiently and cleanly.