In future, it will cover part of the company's electricity requirements. This will create a closed cycle from the production of solar-relevant components to the company's own energy generation.

From flux to kilowatt hour

The system consists of modules that are equipped with our special solar fluxes which guarantee stable soldered connections and high energy yield. In inverters and battery storage systems, too, our electronic flux for reliable connections in power electronics.

„Components whose manufacture was made possible by products that are developed and produced in Eltville every day are therefore working on our own roof.“

Markus Gessner, authorized signatory and head of marketing at Emil Otto GmbH

Signal effect for the solar industry

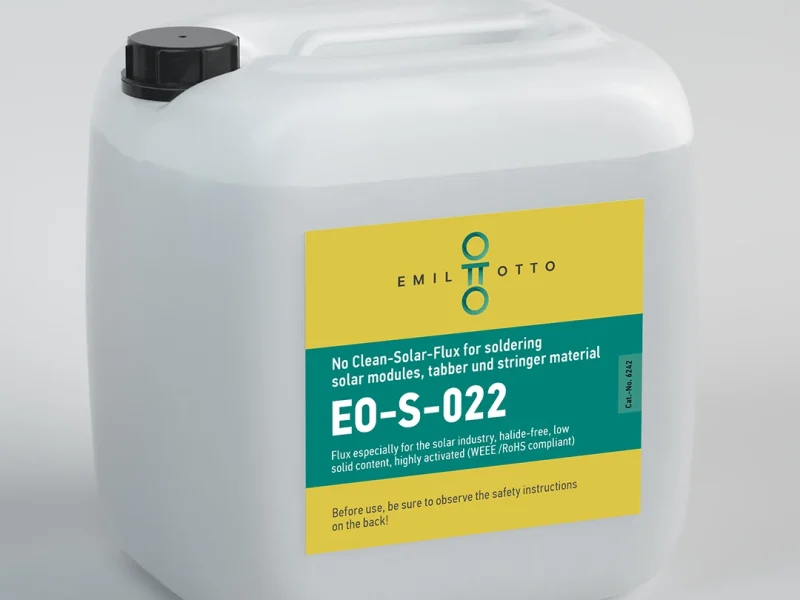

Emil Otto has greatly expanded its portfolio for the photovoltaic industry in recent years. Today, it includes solar fluxes, paste-like flux gels, cleaning media and other consumables for the production of solar cells and modules. In total, more than a dozen specific solar flux variants are now available.

Our new PV system shows how environmentally friendly production processes and renewable energies can work together and how green energy starts with the consumables used.

Outlook

For us, this step means that the added value of the solar industry does not end at the factory gate. It flows back into our own production in the form of clean energy.

More information on solar fluxes, flux gels and cleaning media for photovoltaic production can be found on Emil Otto's solar product page.