Thanks to its zinc- and halide-free formulation and a powerful activator system, the flux offers outstanding wetting properties with minimal residue behavior. The formulation is based on a combination of inorganic activators and complex organic additives, supplemented by highly effective wetting-active components. Thanks to this composition

For processing, the cleaned base material is first slightly preheated, for example by induction, IR emitter, oven, soldering iron, hot air or a flame. The flux is then applied. Further heating is then carried out with the addition of solder until the soldering material melts. To avoid possible corrosion, flux residues must be carefully removed immediately after the soldering process.

"Particularly noteworthy is the possibility of using it when processing Nitinol."

Markus Geßner, Head of Marketing and Sales at Emil Otto GmbH

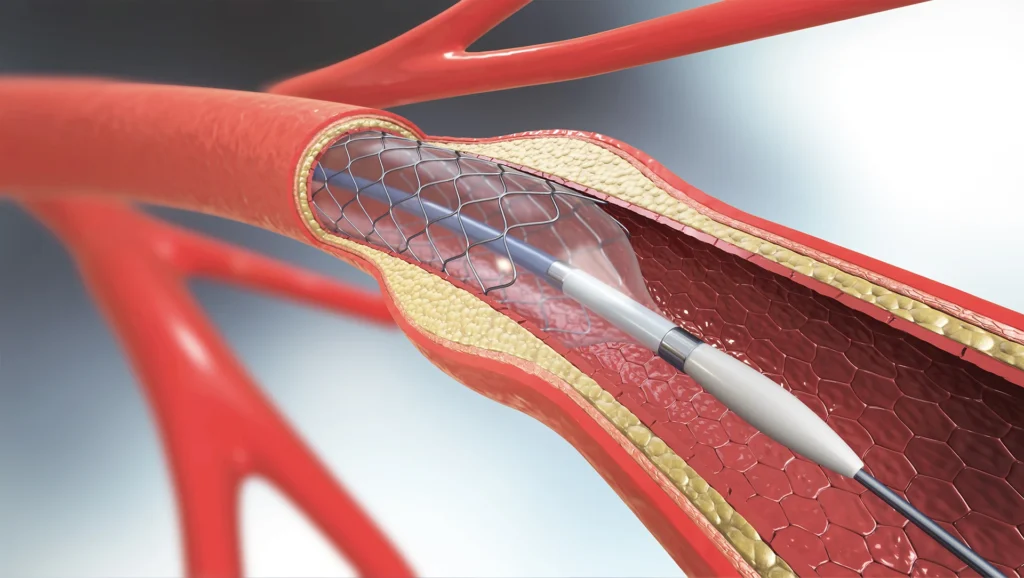

Nitinol is a special alloy of nickel and titanium that is characterized by two extraordinary material properties: the shape memory effect and superelasticity. Thanks to these properties, Nitinol can return to its original shape after being deformed when heated or deform significantly under mechanical stress and immediately return to its original state.

These properties make Nitinol a sought-after material in numerous high-tech applications. In medical technology, Nitinol is primarily used for stents, guide wires, catheters, orthodontic arches and flexible spectacle frames. The alloy is also used in the aerospace industry, for example for temperature-controlled actuators or for vibration damping in sensitive components. In robotics and microsystems technology, Nitinol enables the construction of miniaturized, thermomechanically operated switching elements and grippers. Nitinol is even used in consumer goods such as spring-back cell phone components or robust spectacle frames.

"As nitinol is difficult to solder due to its stable oxide layer, special fluxes are required to produce reliable metallic connections. For such applications, especially in areas with high demands on process reliability and cleanliness, we have developed the highly active flux

EO-M-026 developed."Markus Geßner

EO-M-026

Soldering and tinning processes for nickel alloys as well as 'nitinol'

Ready-to-use, highly concentrated flux

Type: ISO-9454: 3311 (WEEE/RoHS compliant)

The FLUX-REMOVER is available

Find out more about our fluxes for soft soldering a wide variety of metals.